World TOP CLASS Quality

Reasons why Kokusai Paper Maintains Its TOP Quality

Kokusai provides published accuracy specifications that are maintained during use.

This means that there is no need for recalibration of the recorder when the chart is changed.

Kokusai chart papers are serialized.

Systematic lot tracking is used to maintain uniformity and quality.

Critical information including base paper characteristics, finishing specifications and final shipment data is recorded and filed by lot number for each product.

This information is used by production management and material quality control to ensure chart uniformity and quality.

- Serial Number

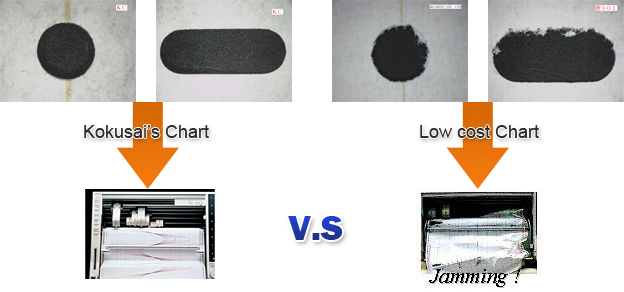

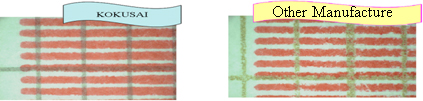

Clear and Accurate Recording on Paper

Kokusais recording chart paper is designed with careful consideration of the recorders operation by working closely with recorder manufacturers. Kokusai works closely with mother coil paper suppliers to ensure that its charts are well suited for use with either pens or ink ribbons to provide clear, distinct recording. Below are samples showing the clarity of recording on our chart papers.

-

- Clear recording

-

- Ink Ribbon

-

- Plotter pen and pens

Considerations for TOP CLASS Recording Charts Inclination of Z-Fold Chart

Affected by humidity and temperature, Z-Fold charts may lean to one side even when it is folded.

This is called inclination.

Inclination results from slight distortion of the paper at the production stage.

Chart paper with inclination may not fit properly in the recorder, or even if it does, it may come loose while the recorder is running, and distort the recording trace.

The importance of maintaining the shape of chart paper

Distortion, twists, and inclination of the chart paper due to the poor raw material quality or rough handling after the coil is cut into sizes will result in distorted, twisted or inclined chart paper that will produce an inaccurate trace.

It may increase the possibility of chart paper coming off the guide holes and resulting stack of paper.

Kokusai puts all chart papers through thorough tests to make sure its charts are accurately manufactured.

Shape of guide holes (driving holes)

Driving pins of the recorder have various sizes and shapes such circle, oval, square, and rectangle.

Although an incorrect size or shape of a charts driving holes may allow it to be placed in a recorder, shrinkage or expansion of the paper caused by change temperature or humidity can cause inconsistent movement of the paper, possibly leading to paper jamming.

A similar situation can occur if the drive pins are too big for the drive holes.

Misshapen drive holes on the chart, or burrs from improper machining may also cause paper flow problems.

Quality Control from Original Coil paper to Final Paper

After thoroughly testing the huge mother coil, including its fiber alignment, Kokusai cuts the over 2-meter diameter coil into a specific size based on the chart to be made.

Different charts require different performance characteristics, and the performance characteristics of paper come from different portions of the mother coil.

Kokusai selects the correct portion of a coil to meet the expected characteristics of the chart.

Kokusai has confidence that their quality control, conforming to ISO9001 and ISO14000 standards, will ensure you receive the quality that you expect in your recording charts.

- Mother coil (paper). Cut mother coil paper.

Special Inks and Precision Films for Better Markings

Chart markings are printed using special inks formulated to not repel the recording pen's ink.

This minimizes ink skipping and blotting in all recording systems and environments.

Taken together, Kokusai's leading-edge plate marking systems and printing techniques prevent even the slightest misalignment during production in the air controlled environment.

Thus, the user is ensured of a clear and accurate recording presentation.

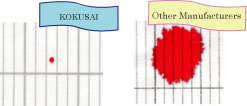

Ability to print high density traces

A quality chart will not show instances of pen snagging, ink blotting or broken trend lines when tested by recording over a width of the chart.

Ability to maintain a drop of ink without blotting over a period of time

Kokusai chart paper is capable of having a ink pen paused on a position without ink spreading out after a period of 24 hours.

Especially in laboratory, it is often the case that pens are left on a chart while the recorder is not running.

It is important for the chart paper to stay clean without the spreading of ink. By leaving the paper stained the ink can spread to the platen roller, resulting in the chart sticking to the roller.

This may result in improper paper flow, or possibly paper jamming.

Packaging

All Kokusai strip, roll and fanfold charts are shipped in individual packaging to maximize shelf life both before and after use.

This is in keeping with Kokusai's belief that its recording charts are precision parts of a technologically sophisticated apparatus.

Strip charts are shrink-wrapped and packaged in a sturdy carton.

This maximizes Accuracy, readability, and ease of storage and retrieval.